- Home

- Agriculture parts

- Combine header parts

- Combine parts

- Grain delivery

- Separation

- Threshing mechanism

- Various components

- Foorage harvester parts

- Salvage

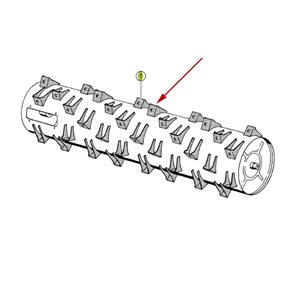

Accelerator / feeder drums

Threshing unit Drums for John Deere, Case IH, New Holland, Claas Lexion, Massey Ferguson combines.

Accelerator and feeder drum are two essential components of a combine harvester that work together to efficiently harvest and thresh crops.

The accelerator is a large, horizontal, rotating drum that is located at the front of the combine harvester. As the harvester moves through the crop field, the crop is fed into the accelerator. The accelerator drum has teeth or paddles that rotate and move the crop towards the feeder drum.

The feeder drum is another rotating cylinder that is located behind the accelerator. The feeder drum has a series of evenly spaced, curved bars that help to pull the crop from the accelerator and feed it into the threshing mechanism. The speed and spacing of the bars on the feeder drum can be adjusted depending on the type of crop being harvested and the condition of the crop.

Together, the accelerator and feeder drum work to efficiently separate the grain from the chaff and other plant material. The crop is fed through the threshing mechanism, where the grain is separated from the rest of the plant material. The grain is collected and stored in a tank while the straw and other debris are ejected out the back of the harvester.

Less