- Home

- Agriculture parts

- Combine header parts

- Combine parts

- Grain delivery

- Separation

- Threshing mechanism

- Various components

- Foorage harvester parts

- Salvage

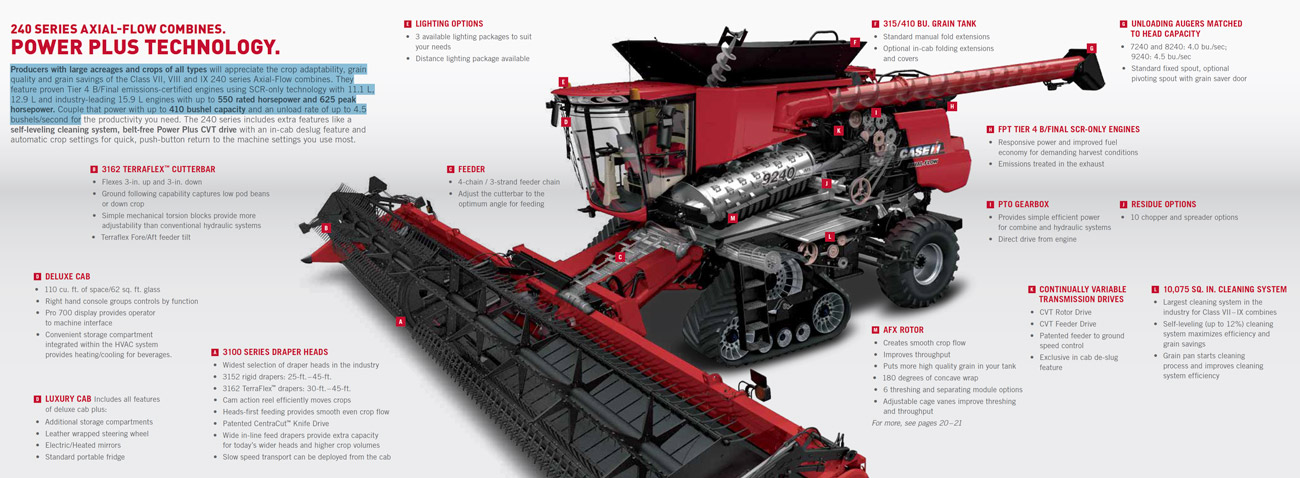

With a Case IH Axial-Flow combine, you’ll have all the capacity you need, as well as easy adjustment options to match your crop and field conditions and minimize potential grain loss. The Case IH AFX rotor creates smooth crop flow, improving throughput and putting more high quality grain in the tank.

Thanks to more space and an ergonomic design, when you climb into the Case IH Axial-Flow cab, you’ll get a panoramic view of what leadership really looks like. When the days are long and the nights are even longer, you’ll come to really appreciate the industry-leading comfort of the Axial-Flow cab.

We understand the importance of making machine adjustments on the go, which is why the Case IH MultiFunction propulsion handle was designed to have the most commonly used controls placed within easy reach. Plus, you’ll be able to work more efficiently thanks to crop presets and the ability to save multiple crop settings in memory. In addition, in-field productivity is enhanced by conveniently grouped functions and a state-of-the-art AFS Pro 700 display for yield monitoring and machine/guidance control.

The simple and reliable Case IH Axial-Flow combine is designed with fewer moving parts to make the most of short harvest windows. Innovative features like the in-cab rotor de-slug, standard on 7240, 8240 and 9240 models, keep you on the go. And with Case IH combines featuring the industry’s longest service intervals, you’ll be sure to maximize your harvest time day after day, season after season.

Axial-Flow single rotor technology has led the industry since 1977, providing a simple design that produces superior grain quality and a better value than any other combine on the market.

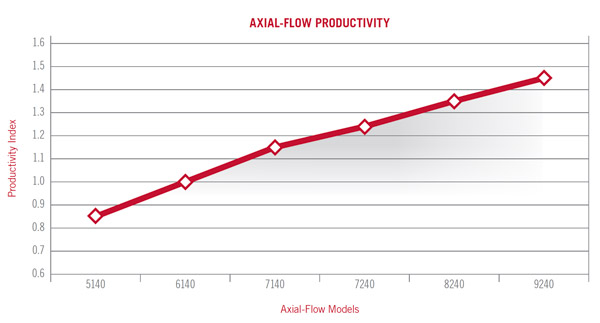

Axial-Flow combine productivity is dependent on several variables: type of crop, crop conditions, timeliness of harvest, machine settings, and operator experience. Adverse harvest conditions early in the season produce lower productivity levels than ideal harvest conditions with optimized machine settings later in the season. Machine capacity may vary, depending on conditions. The average productivity difference between each Axial-Flow model ranges 10 to 20 percent.

| Model | 5140 | 6140 | 7140 | 7240 | 8240 | 9240 |

| Class Size | Class V | Class VI | Class VII | Class VII | Class VIII | Class IX |

| Engine | Case IH ; FPT 6.7 L | Case IH ; FPT 8.7 L | Case IH ; FPT 11.1 L | Case IH ; FPT 12.9 L | Case IH ; FPT 16.0 L | |

| Rated Power | 265 hp | 348 hp | 375 hp | 402 hp | 480 hp | 550 hp |

| Peak Power | 308 hp | 411 hp | 442 hp | 468 hp | 555 hp | 625 hp |

| Power Rise | 43 hp | 63 hp | 67 hp | 66 hp | 75 hp | |

| Feeder Width | 45.5 in. (1.16 m) | 54 in. (1.37 m) | ||||

| Concave Wrap | 156.5° | 180° | ||||

| Cleaning System | Fixed / CrossFlowTM | Self-Leveling to 12.1% | ||||

| Cleaning Area | 8,556 sq. in. (5.5 m2) Fixed / 8,370 sq. in. (5.4 m2) CrossFlow | 10,075 sq. in. (6.9 m2) | ||||

| Grain Tank Size | 250 bu. | 300 bu. | 315 bu. | 410 bu. | ||

| Unload Rate | 2.5 bu./sec | 3.2 bu./sec | 4.0 bu./sec | 4.0 bu./sec | 4.0 bu./sec | 4.5 bu./sec |

| Rotor Drive | 2.25 in. (57.15 mm) rotor belt | 3.0 in. (76.2 mm) rotor belt | Power Plus CVT Drive | |||

| AFS Pro 700 | Standard | |||||

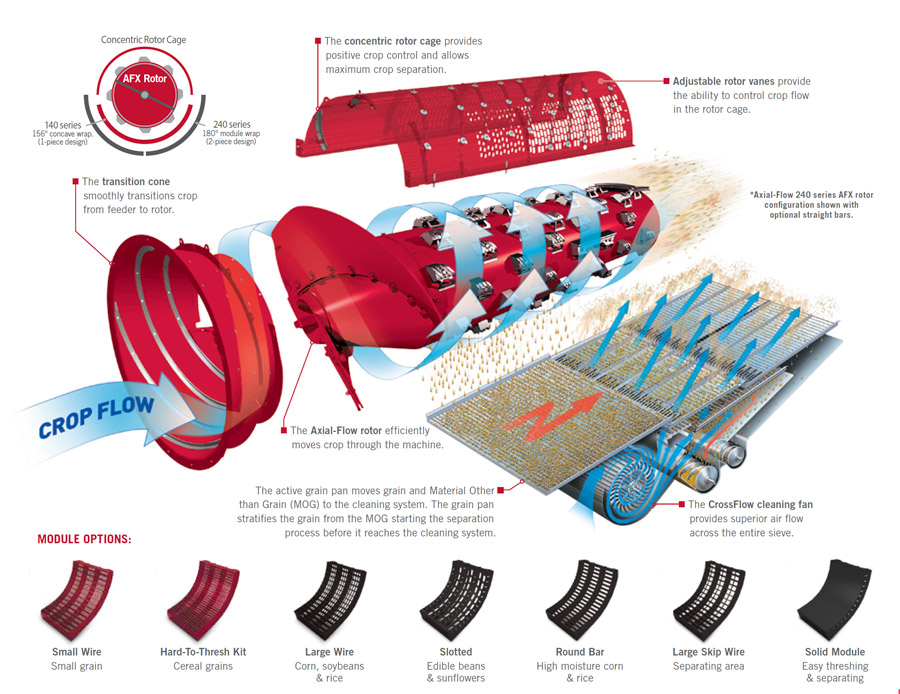

We pioneered rotor development back in the 1960s. Since then, refinements, enhancements, and improvements have led to the pinnacle in rotor performance, the AFX rotor. It features constant pitch impellers that draw the crop and air into the rotor. The AFX rotor can be set into many configurations, adapting to both crop and threshing conditions with the use of straight bars, spiked rasp bars, and helical kickers. Competitive rotor and cage designs can reduce productivity, and increase grain damage because of inefficient feeding and crop-control designs.

The AFX rotor uses constant pitch impellers, rasp bars, and helical kickers to efficiently move crop through the machine for more complete threshing and greater productivity. The constant pitch impellers provide more capacity, using less horsepower and less fuel.

The small tube (ST) rotor is standard for rice and optional for small grain producers. This rotor provides increased productivity in tough harvest conditions where rice or tough green straw would be present.